Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2. Classification according to the working environment

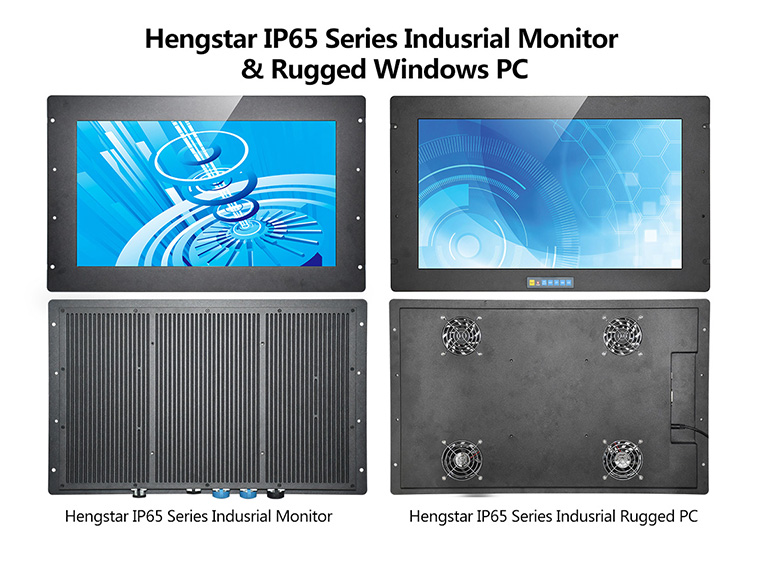

The demand for industrial -grade industrial control machines is high, and it has good adaptability and stability in terms of temperature, humidity, and electromagnetic interference. It can be used in a harsh environment such as the production line and outdoor monitoring of the factory.LET'S GET IN TOUCH

About Us

Related Products List

Contact Us

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.